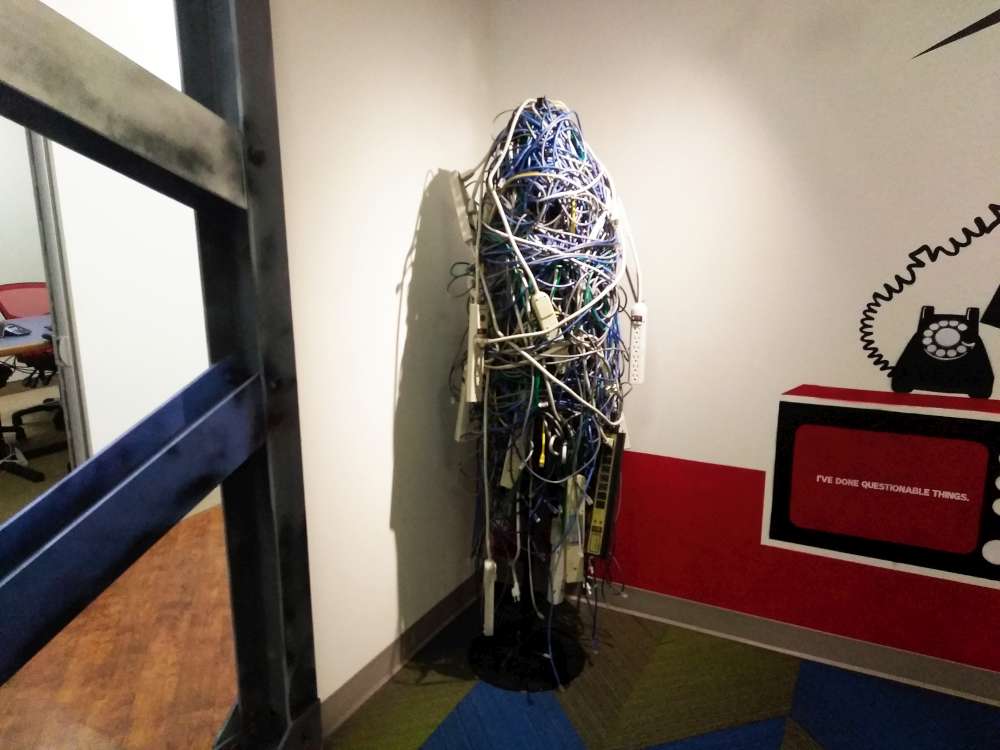

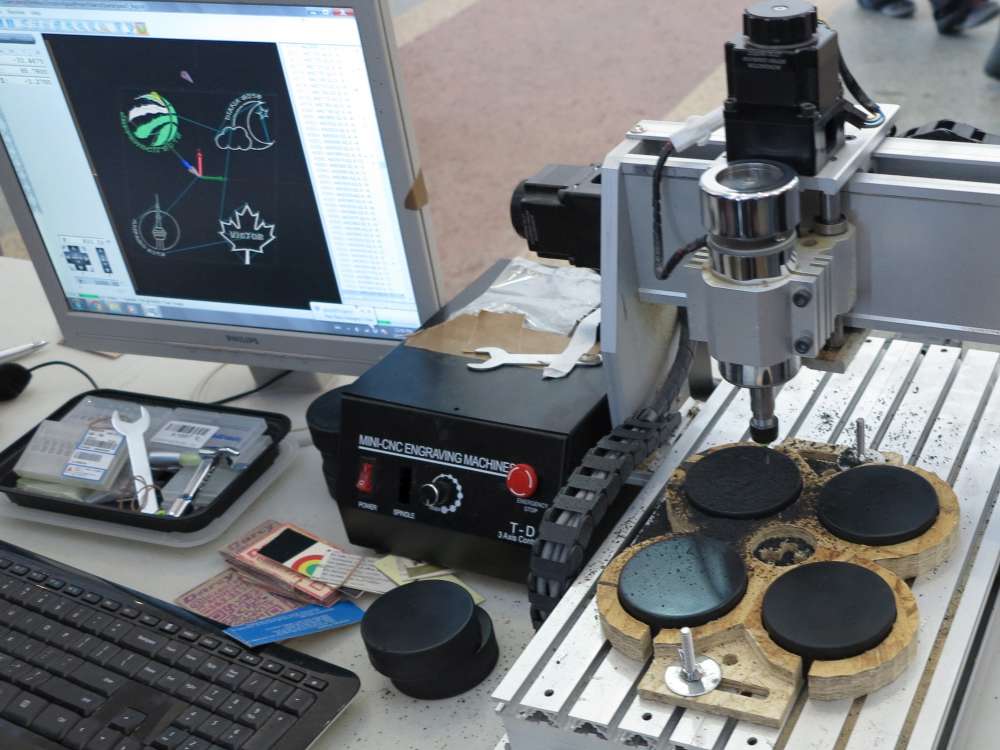

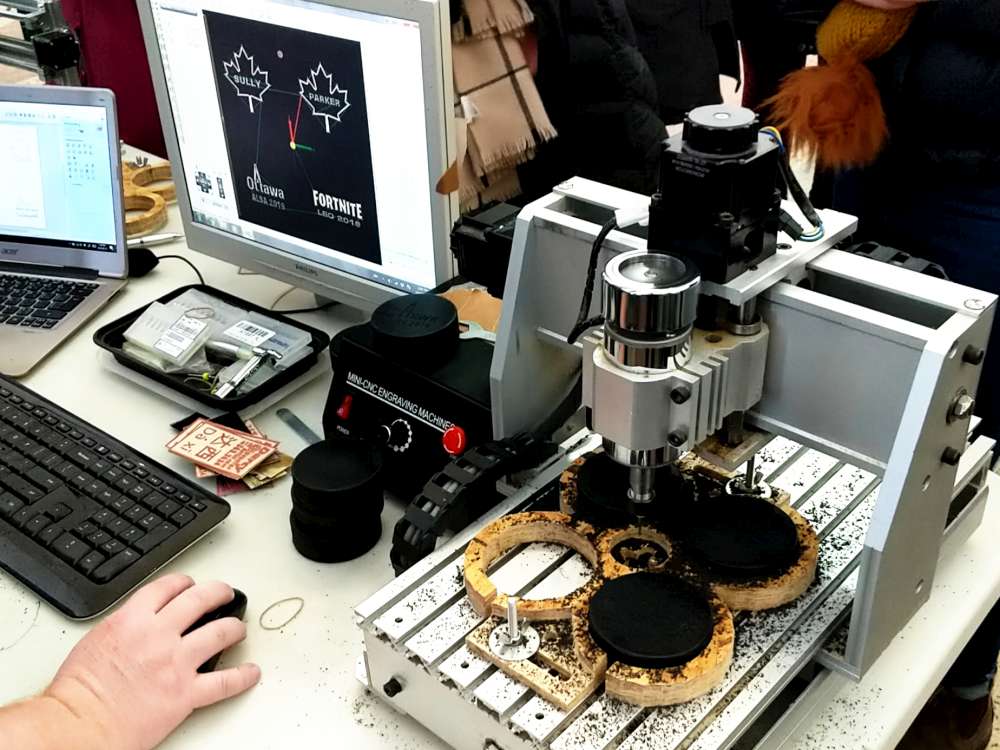

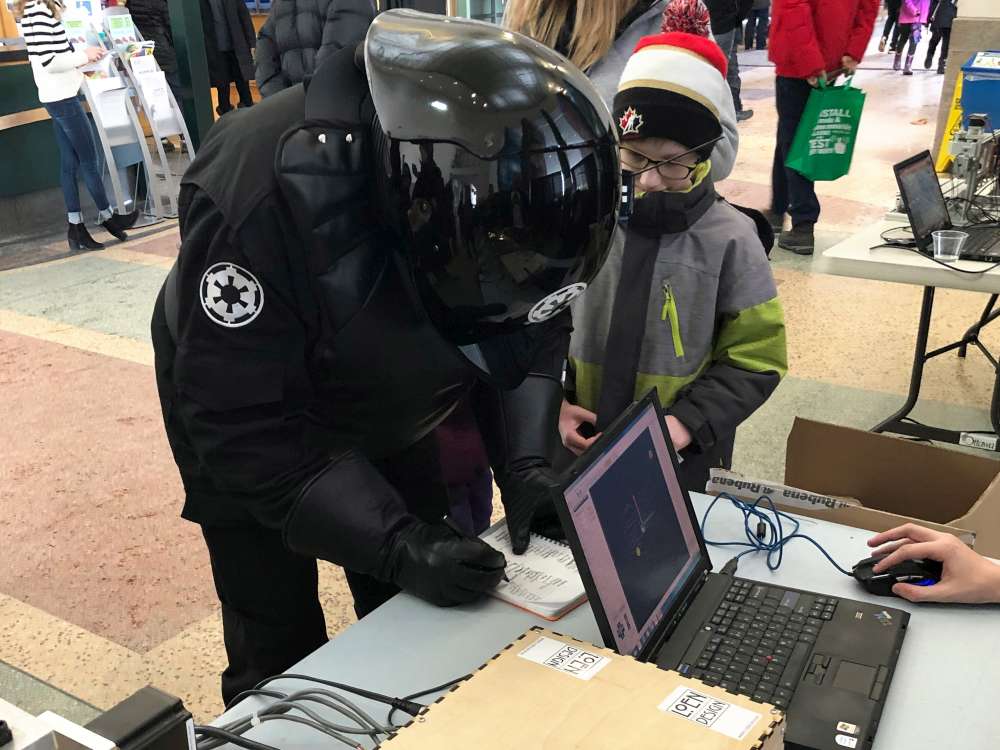

CNC613 is a project to create a shared CNC machine. People can learn to use it and understand their needs and eventually elect to buy a machine or just use the shared machine. The exposure to the machine and community around it would lower the friction for people to buy or adopt this method of fabrication.

It was initiated by Darcy Whyte and the first machine was assembled by Doug Commons and Dave Hunt. A bit of help from Richard Sloan.

We now have a great community of practice around CNC techniques.

Adrian Jones, 6090 with a1.5kW water cooled spindle (http://www.woodsgood.ca/)

Adrian Jones, 6090 with a1.5kW water cooled spindle (http://www.woodsgood.ca/)

Arnold Roos, 3040

Doug Commons, 6040, 9090?, XXXX? (http://www.dnclabs.com/)

Darcy Whyte, 6040, 6040, 3020, 2020

Ray Loomer, 6040

Paul Blais

Joe’s CNC” design, made from MDF and conduit pipe/skate bearings for the rails. The “spindle” is just a Bosch wood router. Approximate work area is 2′ x 4′. Currently fits snugly in an 8’x10′ shed 🙂

Joe’s CNC” design, made from MDF and conduit pipe/skate bearings for the rails. The “spindle” is just a Bosch wood router. Approximate work area is 2′ x 4′. Currently fits snugly in an 8’x10′ shed 🙂

Johnathan Enright, 3040

Dave Hunt, 6090

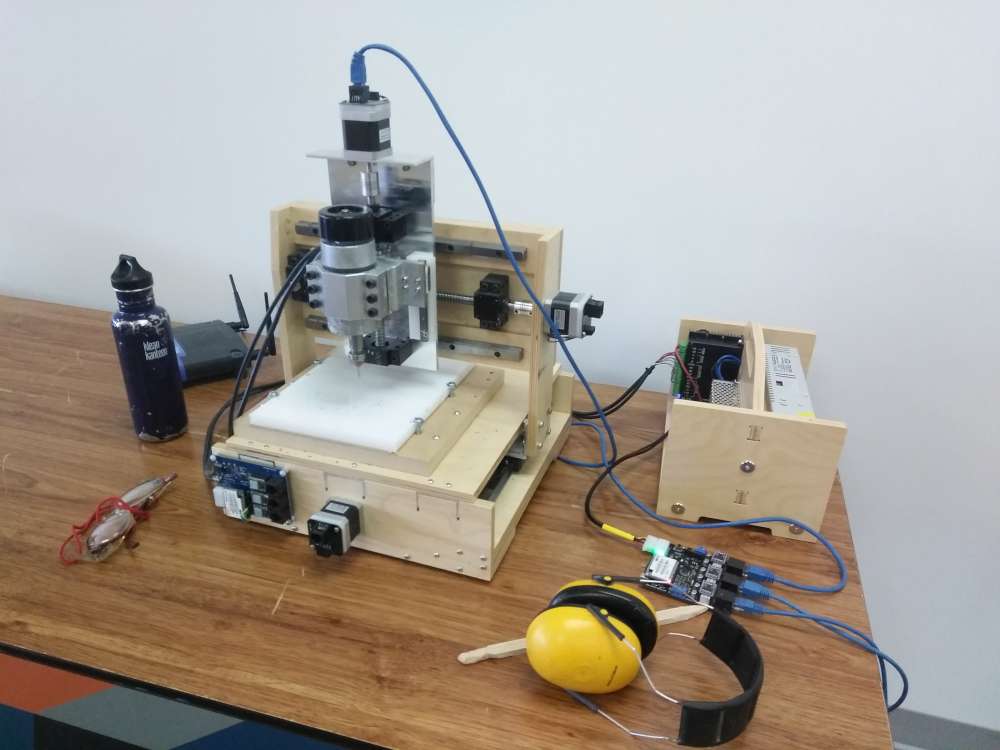

Phonesavanh Thongsouksanoumane, 2020

Phonesavanh Thongsouksanoumane, 2020

Peter Sjoberg

Peter Sjoberg

Cutting area is about 17″x14.5″

Spindle is a 400W brushless dc motor.

Software used is linuxcnc.

Olaf Baumann

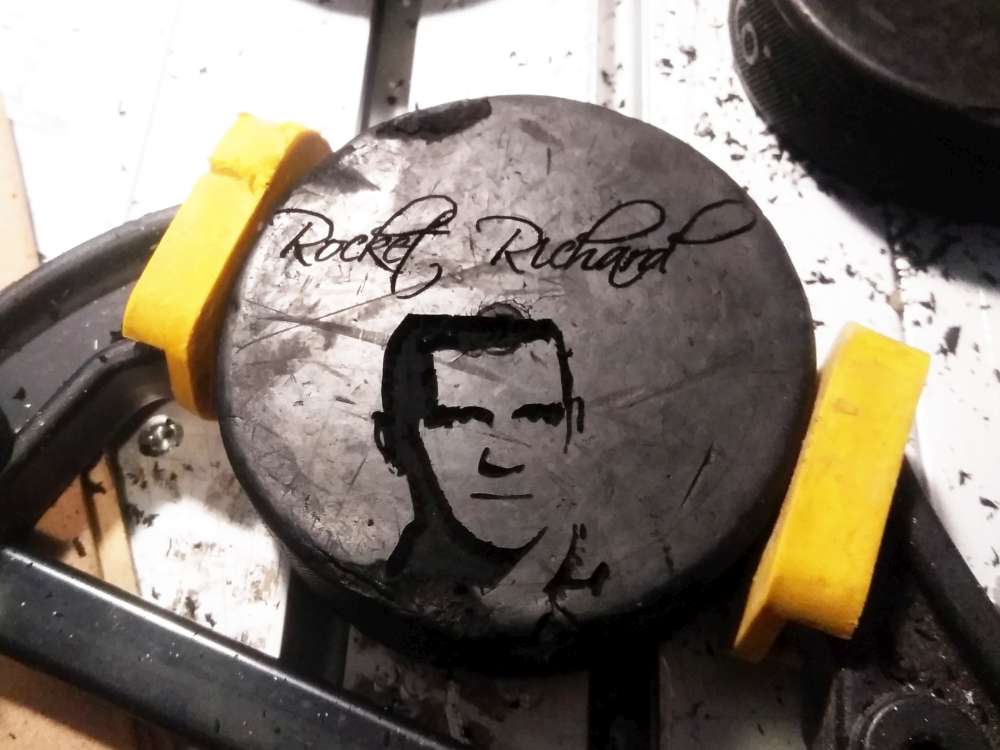

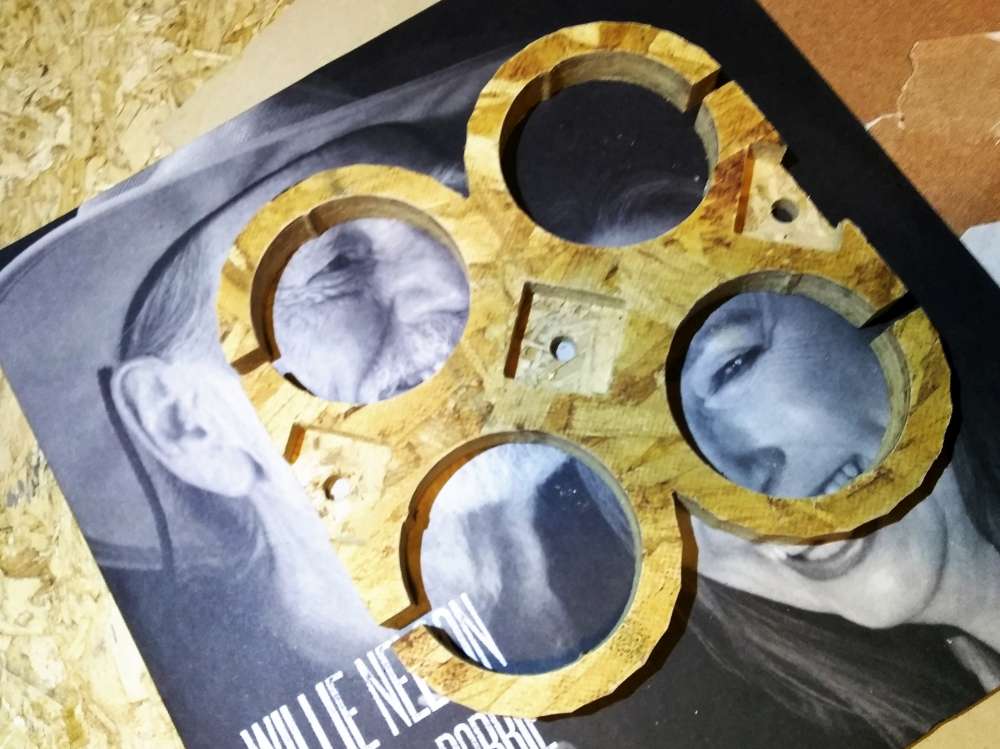

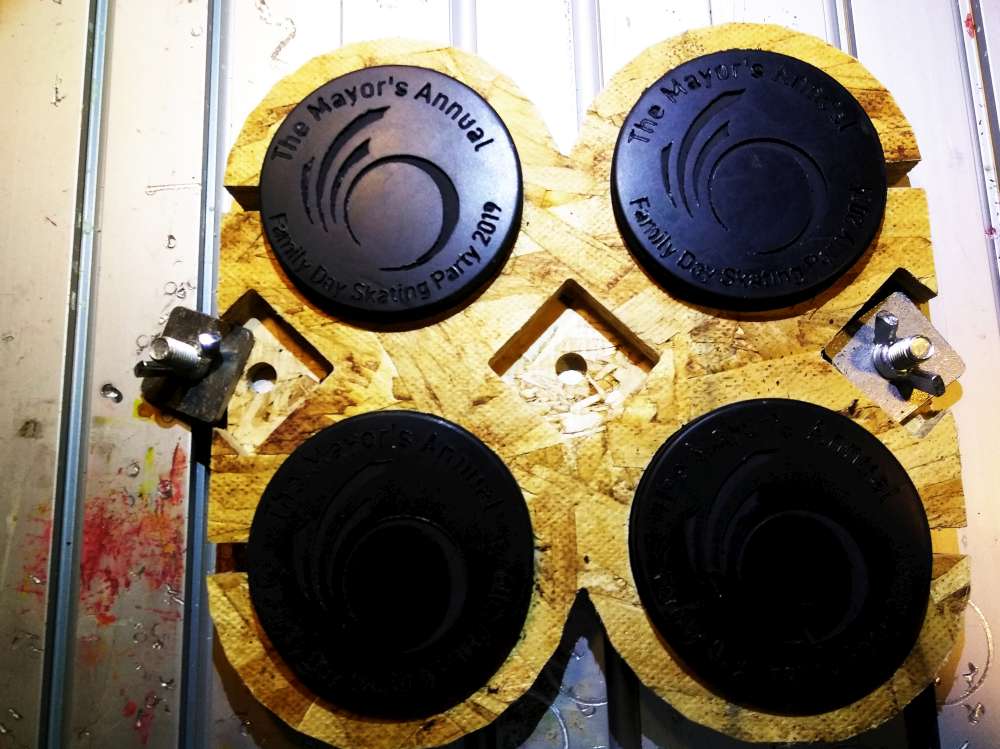

Michel Proulx